Mick'nSarah

Junior Ranger

Hi all!

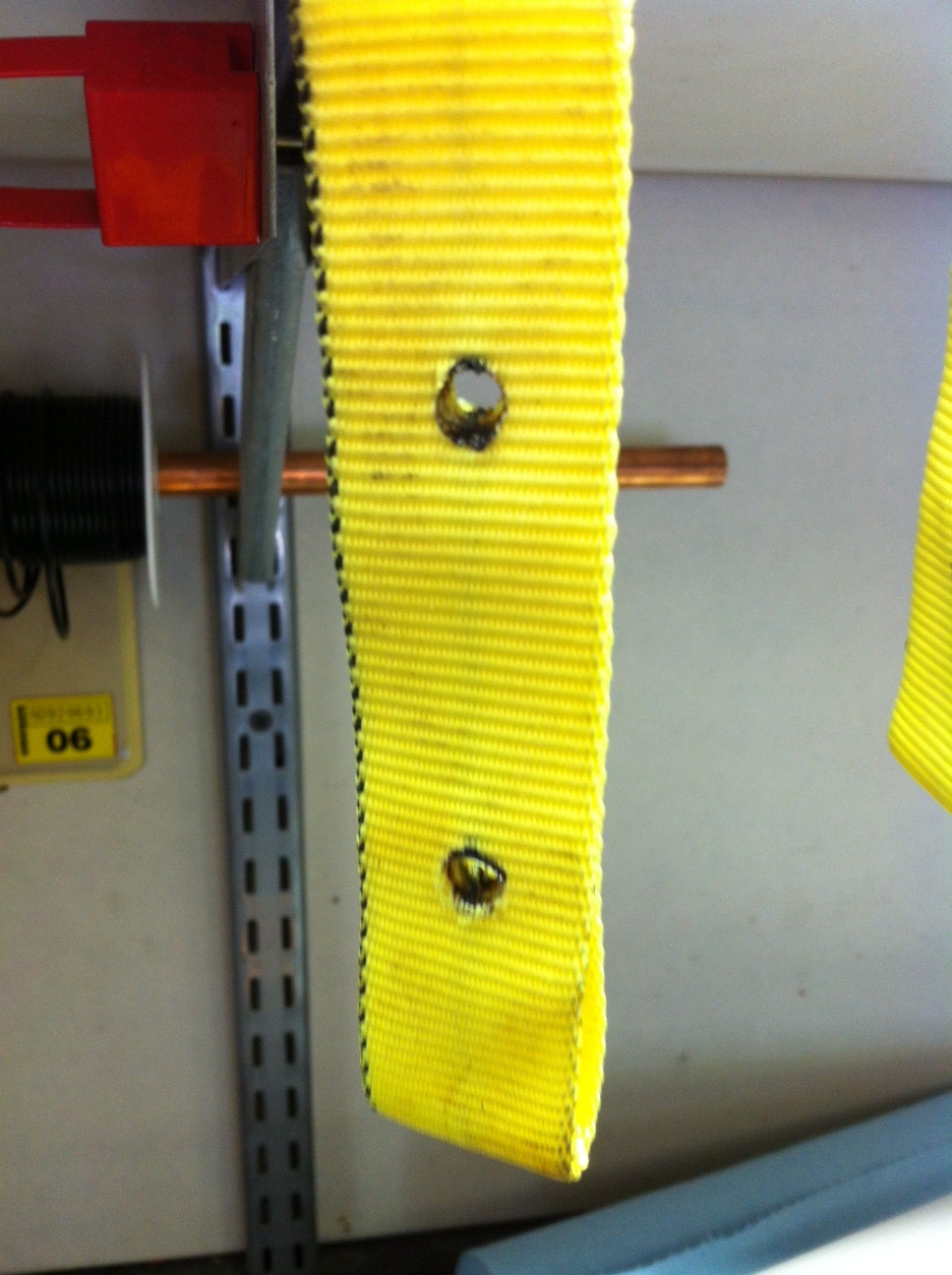

I have been working on a little project today, and thought I would share what I did. I may be late to the party on this (wouldn't be the first time!), but I hadn't seen anything from anyone else.

The fridge doesn't fit in the galley with the handles on, as many know, and I have been lifting it by the very small ledges all this time. Every so often I feel a little click (when it is really full and heavy), and I was getting nervous. Plus, after giving up rock climbing, my fingers are nowhere near as strong as they used to be!

After some thought, I came up with this handle solution. We had most of the parts at home (the screws that came with the handles would have worked, but I swapped them out as I know the parts I used are stainless and won't rust).

Everything slides in easily, and lifting is a breeze!

I have been working on a little project today, and thought I would share what I did. I may be late to the party on this (wouldn't be the first time!), but I hadn't seen anything from anyone else.

The fridge doesn't fit in the galley with the handles on, as many know, and I have been lifting it by the very small ledges all this time. Every so often I feel a little click (when it is really full and heavy), and I was getting nervous. Plus, after giving up rock climbing, my fingers are nowhere near as strong as they used to be!

After some thought, I came up with this handle solution. We had most of the parts at home (the screws that came with the handles would have worked, but I swapped them out as I know the parts I used are stainless and won't rust).

Everything slides in easily, and lifting is a breeze!